UltraSonic Pro X9000

Fully Automatic Industrial Ultrasonic Cleaning System

The next generation of precision cleaning technology designed for manufacturing excellence. Our UltraSonic Pro X9000 delivers unmatched cleaning performance for the most demanding industrial applications across automotive, electronics, medical, and aerospace sectors.

High Efficiency

Reduces cleaning time by up to 60%

Multi-Frequency

20-130kHz adjustable frequency

Smart Control

IoT enabled with remote monitoring

Eco-Friendly

30% lower energy consumption

Years Experience

Global Installations

Cleaning Efficiency

Technical Support

Product Image Gallery

Explore our industrial ultrasonic cleaners from every angle with high-resolution images

Fully Automatic Industrial Ultrasonic Cleaning System

Our flagship model with advanced cleaning technology

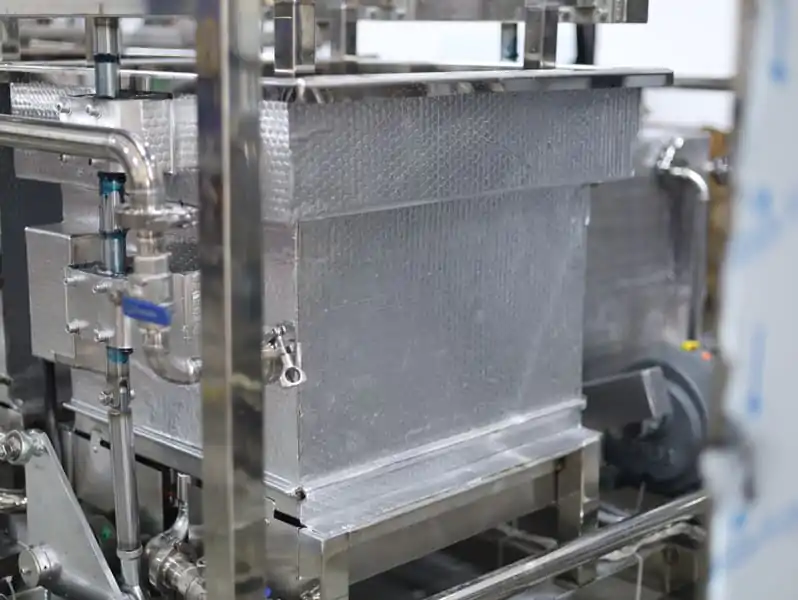

Check Valve

Thermal Insulation Layer

Valve Switch

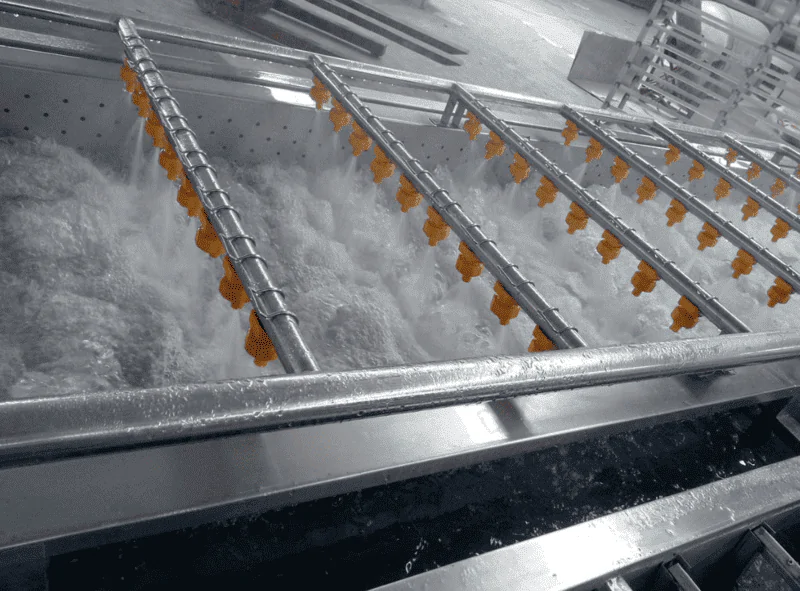

Ultrasonic Cleaner in Operation - Cleaning Automotive Parts

See our equipment in action with real-world applications

Technical Parameters

Our industrial ultrasonic cleaning systems are engineered to deliver superior cleaning performance with precision-controlled parameters for optimal results across various applications.

Ultrasonic Frequency

- Standard: 28kHz, 40kHz

- Multi-frequency: 28/40/80kHz switchable

- High-precision: Up to 130kHz available

Power & Capacity

- Power: 600W - 12,000W (customizable)

- Tank capacity: 30L - 1000L

- Power density: 80-120W/gallon

Temperature Control

- Range: Room temp to 80°C (176°F)

- Precision: ±1°C temperature control

- Heating: SUS316 immersion heaters

Timing & Control

- Timer: 0-999 minutes programmable

- Control: 7" HMI touchscreen interface

- Automation: PLC-controlled process

Construction

- Tank material: SUS304/316L stainless steel

- Transducer: Industrial-grade piezoelectric

- Frame: Powder-coated steel structure

Additional Features

- Filtration: 5-20μm particle filtration

- Agitation: Pneumatic or mechanical options

- IoT: Remote monitoring capability

Customization Options Available

Our engineering team can customize any parameter to meet your specific industrial cleaning requirements. From specialized frequencies for delicate components to expanded tank sizes for larger parts, we design solutions that perfectly match your production needs.

Key Features of Our Industrial Ultrasonic Cleaners

Our fully automatic ultrasonic cleaning systems combine cutting-edge technology with industrial-grade durability to deliver superior cleaning performance for your most demanding applications.

Advanced Multi-Frequency Technology

Equipped with adjustable frequency range (20-130kHz), allowing optimal cleaning for different materials and contaminants. Switch between powerful low-frequency for heavy-duty cleaning and gentle high-frequency for delicate components.

Intelligent Control System

PLC-based control system with 10" touchscreen interface for precise parameter adjustment. Remote monitoring via mobile app allows real-time process tracking, alerts, and maintenance notifications, reducing downtime by up to 30%.

Eco-Friendly Operation

Advanced filtration and recycling system reduces water consumption by up to 60%. Energy-efficient transducers and smart power management decrease electricity usage by 30% compared to conventional systems, supporting your sustainability goals.

Customizable Multi-Stage Process

Modular design with up to 6 processing tanks (pre-wash, ultrasonic cleaning, rinsing, passivation, drying). Each stage can be customized with specific temperature controls, chemical dosing systems, and agitation mechanisms for your industry requirements.

Industrial-Grade Construction

Built with SUS316L stainless steel tanks and reinforced welding for extended durability in harsh industrial environments. High-performance transducers with 100,000+ hour lifespan ensure consistent cleaning power and minimal maintenance requirements.

Industry 4.0 Integration

Seamlessly connects with your production line via standard industrial protocols (PROFINET, EtherNet/IP, Modbus TCP). Data logging and analytics capabilities provide insights for process optimization and predictive maintenance, increasing overall equipment effectiveness.

Custom Solutions for Your Industry

Whether you're in automotive, electronics, medical, aerospace, or any precision manufacturing industry, our engineering team can design a tailored ultrasonic cleaning system that meets your specific requirements.

Product Comparison

Compare our ultrasonic cleaning equipment models to find the perfect solution for your industrial cleaning needs

| Features | Standard Series | Professional Series | Enterprise Series |

|---|---|---|---|

| Tank Capacity | 20-100L | 100-300L | 300-1000L |

| Ultrasonic Frequency | 28kHz | 28/40kHz Dual | 28/40/80kHz Multi |

| Power Density | 80-100W/L | 100-150W/L | 150-200W/L |

| Temperature Range | RT-80°C | RT-90°C | RT-95°C |

| Control System | Basic PLC | Advanced PLC with HMI | Smart IoT System |

| Automation Level | Semi-automatic | Fully automatic | Fully automatic with AI |

| Filtration System | Basic | Advanced with recycling | Multi-stage with water treatment |

| Material | SUS304 | SUS304/316L | SUS316L/Titanium options |

| Energy Efficiency | Standard | Energy-saving | Ultra-efficient with heat recovery |

| Ideal For | Small manufacturers, Automotive parts | Electronics, Medical devices | Aerospace, Semiconductor, Pharmaceutical |

Standard Series

Perfect for small to medium businesses requiring reliable cleaning performance for general industrial applications.

Professional Series

Advanced cleaning capabilities for industries requiring precision cleaning with higher throughput and automation.

Enterprise Series

State-of-the-art ultrasonic cleaning systems for critical applications requiring the highest standards of cleanliness.

Not sure which model is right for your application? Our experts can help you select the perfect ultrasonic cleaning solution.

Frequently Asked Questions

Get answers to common questions about our industrial ultrasonic cleaning equipment

Ultrasonic cleaning uses high-frequency sound waves (20kHz-1MHz) to create millions of microscopic bubbles in a liquid solution. These bubbles implode with tremendous force (cavitation), creating micro-jets that blast contaminants from surfaces without damaging the parts. This technology is particularly effective for removing micron-level contaminants from complex geometries and hard-to-reach areas.

Our equipment serves diverse industries including automotive/transportation (engine parts, fuel injectors), electronics/semiconductor (PCBs, chips), medical/pharmaceutical (surgical instruments, implants), aerospace/defense (turbine blades, precision components), metal processing/manufacturing (bearings, molds), optical/precision instruments (lenses, measuring tools), food/beverage (processing equipment), energy/chemical (filters, reactors), jewelry, printing (cleaning plates), and environmental (wastewater treatment equipment).

Fully automatic systems offer numerous benefits: increased productivity (24/7 operation capability), consistent cleaning quality (eliminating human variables), reduced labor costs (minimal operator intervention), improved safety (reduced chemical handling), optimized resource usage (precise control of water, chemicals, and energy), data tracking capabilities (for quality control), and seamless integration with existing production lines. These advantages typically result in a return on investment within 12-24 months.

We offer extensive customization including tank size/configuration, frequency options (single or multi-frequency from 20kHz to 130kHz), automation level (semi to fully automatic), material handling systems (conveyors, robotics), specialized fixtures for specific parts, integrated filtration/water treatment, heating/cooling systems, advanced control interfaces (touchscreen HMI, IoT connectivity), and industry-specific features (e.g., clean room compatibility for semiconductors or validation packages for medical applications).

Our systems are designed for minimal maintenance, but regular care ensures optimal performance: daily inspection of fluid levels and cleaning solution quality, weekly checks of filtration systems, monthly inspection of transducers and generators, quarterly professional calibration of ultrasonic output, and annual comprehensive service. We offer preventive maintenance packages and remote monitoring options to maximize uptime and equipment lifespan.

Our systems incorporate numerous eco-friendly features: energy-efficient generators (reducing power consumption by up to 30%), water recycling systems (reducing water usage by up to 80%), compatibility with biodegradable cleaning solutions, filtration systems that extend solution life, heat recovery systems, and smart controls that optimize resource usage. These features help companies meet environmental regulations while reducing operational costs.

Still have questions about our industrial ultrasonic cleaning solutions?