Standard Industrial Ultrasonic Cleaner

Professional-grade ultrasonic cleaning equipment designed for industrial applications with advanced cavitation technology for superior cleaning results.

Product Image Gallery

Explore our industrial ultrasonic cleaners from every angle with high-resolution images

Standard Industrial Ultrasonic Cleaner - 40L Capacity

Our flagship model with advanced cleaning technology

Side View with Control Panel

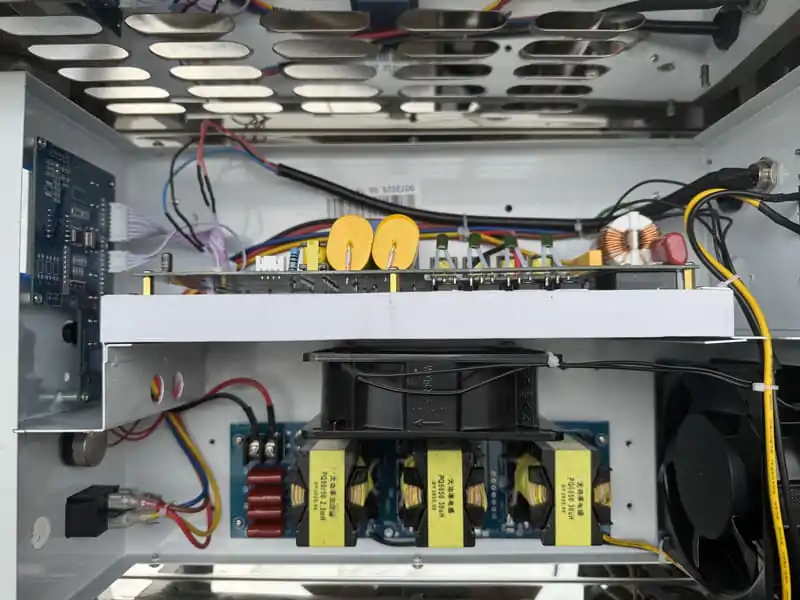

Interior Tank with Transducers

Digital Control Panel Interface

Ultrasonic Cleaner in Operation - Cleaning Automotive Parts

See our equipment in action with real-world applications

Technical Parameters

Comprehensive specifications of our standard industrial ultrasonic cleaner, designed for optimal performance across various applications.

| Parameter | Specification | Description |

|---|---|---|

| Model | UC-2000S | Standard industrial grade ultrasonic cleaner |

| Tank Capacity | 40L (10.5 gallons) | Optimal for medium-sized components and batch cleaning |

| Tank Dimensions | 500 × 300 × 300 mm | Internal dimensions (L×W×H) |

| Ultrasonic Power | 600W (adjustable) | High-efficiency cleaning with power regulation |

| Frequency | 28/40 kHz (dual frequency) | Switchable for different cleaning requirements |

| Heating Power | 2000W | Rapid heating with temperature control |

| Temperature Range | Room temp to 80°C | Digital temperature control with ±1°C precision |

| Timer | 0-99 minutes | Digital timer with auto shut-off |

| Material | SUS304 stainless steel | Corrosion-resistant tank and housing |

| Power Supply | 220V/380V, 50/60Hz | Available in single or three-phase configurations |

Control System

Advanced digital control panel with LCD display for precise parameter adjustment and monitoring. Includes memory function for storing up to 10 cleaning programs.

Safety Features

Equipped with overheat protection, liquid level sensors, and emergency stop button. CE certified with IP54 protection rating for control components.

Optional Accessories

Compatible with filtration systems, basket holders, and specialized fixtures. Upgradable with oil skimmer, automatic lid, and IoT connectivity module for remote monitoring.

Product Features

Our standard industrial ultrasonic cleaners combine cutting-edge technology with robust design to deliver superior cleaning performance for your manufacturing needs.

High-Efficiency Transducers

Advanced piezoelectric transducers deliver powerful 40kHz ultrasonic waves, creating optimal cavitation for thorough cleaning while minimizing energy consumption.

Industrial-Grade Construction

Constructed with SUS304 stainless steel tanks and robust welding techniques, our cleaners withstand harsh industrial environments and provide years of reliable service.

Precision Temperature Control

Digital temperature control system maintains optimal cleaning solution temperature (20-80°C) with ±1°C accuracy, enhancing cleaning effectiveness for various contaminants.

Programmable Timer

Set cleaning cycles from 1-99 minutes with our digital timer system, allowing for precise process control and consistent results across production batches.

Integrated Filtration System

Optional filtration system continuously removes contaminants from cleaning solution, extending bath life by up to 300% and reducing operational costs while improving cleaning quality.

Adjustable Power Output

Fine-tune ultrasonic power from 40-100% to accommodate delicate components or tackle stubborn contaminants, providing versatility across different cleaning applications.

Product Comparison

Compare our standard industrial ultrasonic cleaner models to find the perfect solution for your cleaning needs

| Model | UC-1000 | UC-2000 | UC-3000 |

|---|---|---|---|

| Tank Capacity | 10L | 20L | 30L |

| Ultrasonic Power | 300W | 600W | 900W |

| Frequency | 40kHz | 40kHz | 28/40kHz Dual |

| Heating Power | 500W | 800W | 1200W |

| Temperature Range | RT-80°C | RT-80°C | RT-90°C |

| Timer Range | 1-30 min | 1-99 min | 1-99 min |

| Material | SUS304 | SUS304 | SUS316L |

| Control Panel | Digital | Digital | Touch Screen |

| Best For | Small Parts | Medium Parts | Large Components |

Custom Solutions Available

Need a specialized solution? We offer custom ultrasonic cleaning systems tailored to your specific requirements and industry needs.

Download Full Specifications

Get detailed technical specifications, installation guides, and maintenance manuals for all our ultrasonic cleaner models.

Frequently Asked Questions

Get answers to common questions about our industrial ultrasonic cleaners and how they can benefit your specific application.

Ultrasonic cleaning uses high-frequency sound waves (typically 20-130kHz) to create millions of microscopic bubbles in a liquid solution. These bubbles implode with tremendous force (cavitation), creating a scrubbing action that reaches into crevices and removes contaminants at the microscopic level without damaging the parts being cleaned.

Our industrial ultrasonic cleaners effectively remove oils, greases, waxes, fingerprints, polishing compounds, buffing compounds, flux residues, carbon deposits, light rust, mineral deposits, biological matter, and micron-sized particles from various surfaces and materials.

Most hard materials are safe for ultrasonic cleaning, including metals, glass, ceramics, hard plastics, and circuit boards. However, some soft materials like certain rubber compounds, some soft plastics, and delicate items may not be suitable. We recommend testing a sample piece first or consulting with our engineers for specific material compatibility.

Lower frequencies (20-40kHz) produce larger cavitation bubbles with more cleaning power, ideal for removing heavy or stubborn contaminants from robust parts. Higher frequencies (40-130kHz) create smaller bubbles for gentler cleaning, perfect for delicate or precision components. Multi-frequency systems offer versatility for various cleaning needs. Our technical team can help determine the optimal frequency for your specific application.

The optimal cleaning solution depends on your specific contaminants and materials. We offer a range of environmentally friendly, water-based solutions designed for different industries and applications. Our technical support team can recommend the most effective solution for your needs, whether you require degreasing, oxide removal, precision cleaning, or specialized applications.

Yes, we specialize in both standard and custom-designed ultrasonic cleaning systems. Our engineering team can develop solutions tailored to your specific requirements, including tank size, frequency, power density, automation level, material handling, and integration with existing production lines. Contact us to discuss your unique cleaning challenges.

Our industrial ultrasonic cleaners are designed for minimal maintenance. Regular care includes changing cleaning solutions as needed, cleaning filters, inspecting transducers, and checking electrical connections. We provide comprehensive maintenance guidelines with each unit and offer service contracts for routine maintenance to ensure optimal performance and longevity of your equipment.

Most customers experience ROI within 6-18 months, depending on their application. Benefits include reduced labor costs (up to 80% compared to manual cleaning), decreased cleaning chemical usage, improved cleaning quality leading to fewer rejects, faster processing times, and extended lifespan of cleaned parts. We can help calculate the potential ROI for your specific operation.

Still have questions? Our technical experts are ready to help.