Ultrasonic Cleaning Solutions for Aerospace & Defense

Advanced cleaning technology designed specifically for the demanding standards of aerospace and defense applications, ensuring precision, reliability, and compliance with industry regulations.

Industry-leading ultrasonic cleaning systems for critical aerospace components

Industry Overview

Stringent Quality Standards

Aerospace and defense manufacturing demands the highest level of cleanliness and precision to ensure safety and reliability in critical applications.

Regulatory Compliance

Our ultrasonic cleaning systems help manufacturers meet strict industry regulations including AS9100, NADCAP, and military specifications.

Technological Innovation

Advanced ultrasonic technology provides superior cleaning for complex geometries and removes contaminants conventional methods cannot reach.

Industry-Specific Challenges

The aerospace and defense sectors face unique challenges in component cleaning, including:

- Removal of machining oils, carbon deposits, and other contaminants from complex parts

- Cleaning of intricate geometries and hard-to-reach areas

- Maintaining material integrity while achieving thorough cleaning

- Meeting strict cleanliness verification requirements

Trusted by Industry Leaders

Our ultrasonic cleaning solutions are deployed by leading aerospace and defense manufacturers worldwide.

Ultrasonic Cleaning Solutions for Aerospace & Defense

Our specialized ultrasonic cleaning systems are engineered to meet the rigorous standards of aerospace and defense manufacturing, where precision, reliability, and compliance are non-negotiable.

Military-Grade Cleaning Systems

Our MIL-SPEC compliant systems remove contaminants down to micron level, ensuring critical components meet stringent defense requirements for performance and reliability.

Aircraft Component Cleaning

Specialized solutions for turbine blades, hydraulic systems, and avionics components that remove oils, carbon deposits, and particulates without damaging sensitive materials.

Precision Cleaning for Electronics

High-frequency ultrasonic systems (80-130kHz) for delicate electronic components, circuit boards, and sensors used in navigation, communication, and weapons systems.

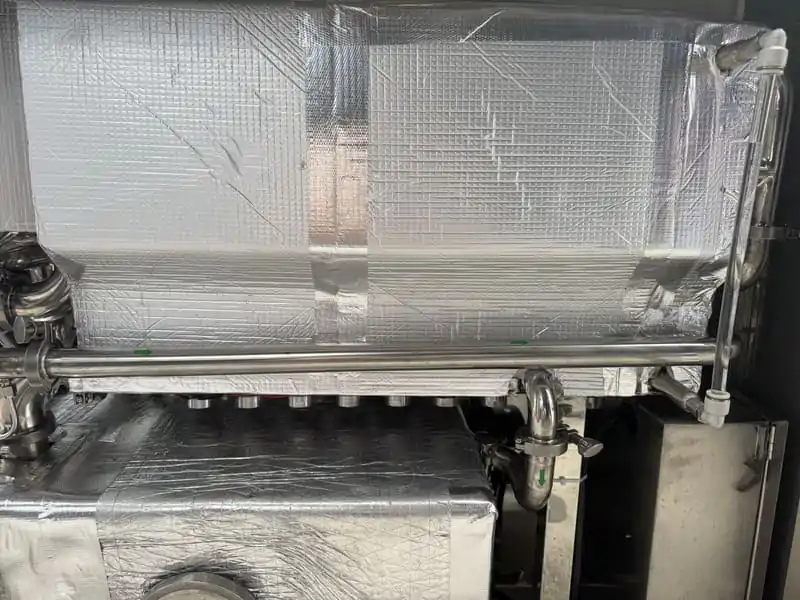

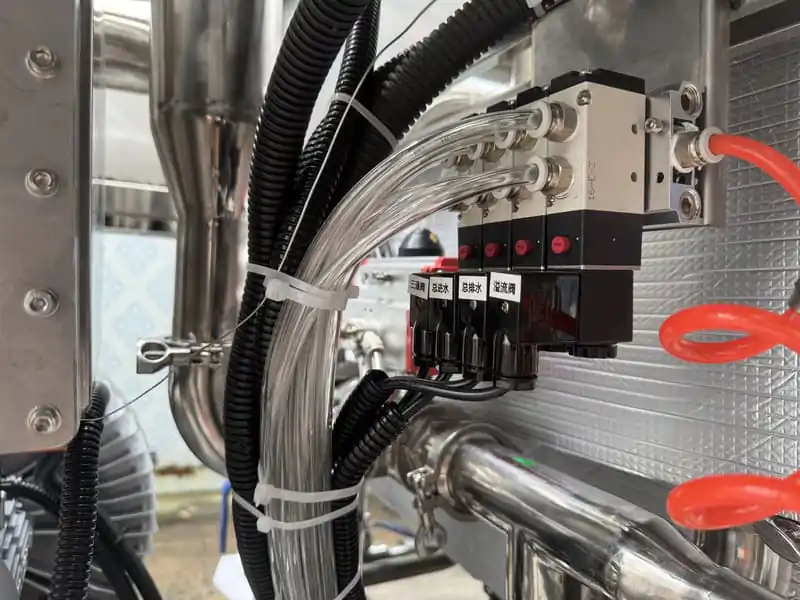

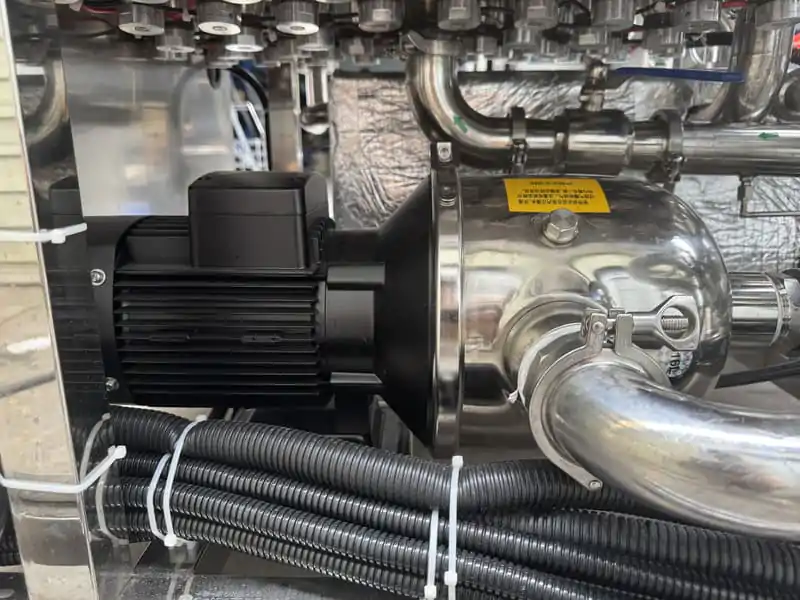

Multi-Stage Aerospace Cleaning System

Our Industrial Ultrasonic Cleaning Equipment

Discover our comprehensive range of professional ultrasonic cleaning solutions designed for precision cleaning across multiple industries

Standard Industrial Ultrasonic Cleaner

Compact and efficient cleaning solutions perfect for laboratories, jewelry, and precision instruments. Capacity: 1-20L

Semi-Automatic Industrial Ultrasonic Cleaner

Semi-automated systems for automotive, electronics, and medical device manufacturing. Capacity: 20-200L

Why Choose Our Ultrasonic Cleaning Equipment?

Advanced Cavitation Technology

Precision-engineered transducers deliver optimal cavitation for thorough cleaning without damage

Customizable Solutions

Tailored designs to meet specific industry requirements and production volumes

Eco-Friendly Operation

Reduces chemical usage by up to 80% while maintaining superior cleaning performance

Our Contribution to Aerospace & Defense

Advancing precision cleaning standards through innovative ultrasonic technology to meet the rigorous demands of aerospace and defense manufacturing.

Enhanced Quality Assurance

Our ultrasonic cleaning systems have helped reduce component failure rates by up to 35% in critical aerospace applications by eliminating microscopic contaminants that conventional cleaning methods miss.

- Meets AS9100 and NADCAP certification requirements

- Documented 99.8% cleanliness verification

- Traceable cleaning processes for regulatory compliance

Environmental Impact Reduction

Our systems have helped aerospace manufacturers reduce hazardous chemical usage by 60% while maintaining superior cleaning results, supporting sustainability initiatives across the defense sector.

- Reduced water consumption by 40% through advanced filtration

- Eliminated use of ozone-depleting solvents

- Energy-efficient operation with 30% lower carbon footprint

Operational Efficiency Gains

Our automated ultrasonic cleaning systems have helped defense contractors reduce processing time by 45% and labor costs by 30%, accelerating production cycles for mission-critical components.

- Reduced cleaning cycle times from hours to minutes

- 25% improvement in throughput capacity

- ROI typically achieved within 14-18 months

Revolutionizing F-35 Component Cleaning

When a leading defense contractor faced challenges with precision cleaning of titanium turbine components for the F-35 fighter jet program, our custom multi-frequency ultrasonic system delivered:

- 99.99% particle removal - exceeding military specifications

- 68% reduction in cleaning-related production delays

- Zero rejection rate for cleaned components over 18 months

Frequently Asked Questions

Common questions about our ultrasonic cleaning solutions for the aerospace and defense industry

How do ultrasonic cleaners benefit aerospace components?

Ultrasonic cleaning provides superior results for aerospace components by removing contaminants from complex geometries and hard-to-reach areas without mechanical scrubbing. The cavitation process effectively removes oils, greases, carbon deposits, and particulate matter down to the micron level, ensuring components meet strict aerospace quality and safety standards. This non-abrasive cleaning method preserves critical surface finishes and dimensional tolerances essential for flight safety.

What aerospace components can be cleaned with your systems?

Our ultrasonic cleaning systems are suitable for a wide range of aerospace components including turbine blades, fuel injectors, hydraulic components, bearings, gears, electronic assemblies, heat exchangers, landing gear components, fasteners, and precision machined parts. We also offer specialized solutions for composite materials and additive manufactured components with customized frequency and chemistry options to ensure safe and effective cleaning.

Do your systems meet aerospace industry standards?

Yes, our ultrasonic cleaning systems are designed to meet and exceed aerospace industry standards including AS9100, NADCAP requirements, and military specifications. Our equipment complies with international standards for cleanliness verification such as NAS 1638 and ISO 16232. We provide full documentation packages for quality assurance and can assist with process validation to ensure compliance with specific OEM requirements and industry regulations.

What cleaning chemistries are compatible with aerospace materials?

We offer specialized aerospace-grade cleaning chemistries that are compatible with aluminum alloys, titanium, high-strength steels, composites, and sensitive electronic components. Our solutions include non-corrosive, low-foaming formulations that effectively remove aerospace-specific contaminants like carbon deposits, hydraulic fluids, and specialized lubricants. All cleaning agents are thoroughly tested for material compatibility and can be customized to meet specific aerospace manufacturer requirements.

How do you ensure cleanliness verification for defense applications?

For defense applications, we implement rigorous cleanliness verification protocols including particle counting, surface analysis, and contamination testing. Our systems can be integrated with automated inspection equipment for real-time cleanliness verification. We provide training on proper testing methods and can develop custom verification protocols to meet specific military standards. Documentation and traceability features ensure compliance with defense contractor requirements and government regulations.

What maintenance is required for aerospace ultrasonic systems?

Our aerospace ultrasonic cleaning systems require regular but minimal maintenance. This includes periodic inspection of transducers, replacement of cleaning solutions based on contamination levels, filtration system maintenance, and calibration of control systems. We provide comprehensive maintenance schedules, training for technical staff, and offer preventive maintenance service contracts. Remote monitoring capabilities allow for predictive maintenance, minimizing downtime in critical aerospace manufacturing environments.

Can your systems handle classified or sensitive components?

Yes, we design secure cleaning systems for classified and sensitive defense components with enhanced security features. These include restricted access controls, data encryption for networked systems, and compliance with relevant security protocols. Our team can work within secure facilities, and we can provide personnel with appropriate security clearances for installation and service. We also offer standalone systems that operate without external network connections when required for maximum security.

What is the ROI timeline for aerospace ultrasonic cleaning systems?

Most aerospace customers achieve ROI within 12-24 months through reduced labor costs, decreased chemical usage, extended component life, and improved quality outcomes. Our systems typically reduce cleaning time by 60-80% compared to manual methods while improving cleaning consistency. Additional value comes from reduced rework rates, decreased warranty claims, and the ability to reclaim previously scrapped components. We provide detailed ROI analysis tailored to your specific application and production volume.