Industrial Ultrasonic Cleaning Systems

High-performance ultrasonic cleaning equipment engineered for precision industries. Our systems deliver superior cleaning results for components requiring micron-level cleanliness.

Our Industrial Ultrasonic Cleaning Equipment

Discover our comprehensive range of professional ultrasonic cleaning solutions designed for precision cleaning across multiple industries

Standard Industrial Ultrasonic Cleaner

Compact and efficient cleaning solutions perfect for laboratories, jewelry, and precision instruments. Capacity: 1-20L

Semi-Automatic Industrial Ultrasonic Cleaner

Semi-automated systems for automotive, electronics, and medical device manufacturing. Capacity: 20-200L

Why Choose Our Ultrasonic Cleaning Equipment?

Advanced Cavitation Technology

Precision-engineered transducers deliver optimal cavitation for thorough cleaning without damage

Customizable Solutions

Tailored designs to meet specific industry requirements and production volumes

Eco-Friendly Operation

Reduces chemical usage by up to 80% while maintaining superior cleaning performance

Core Competencies

Our comprehensive capabilities ensure superior ultrasonic cleaning solutions from design to delivery

Design & Manufacturing Excellence

1000m² Factory Showcase

State-of-the-art manufacturing facility equipped with advanced production lines and quality control systems

100+ Professional Team

Experienced engineers, technicians, and quality specialists dedicated to ultrasonic cleaning technology

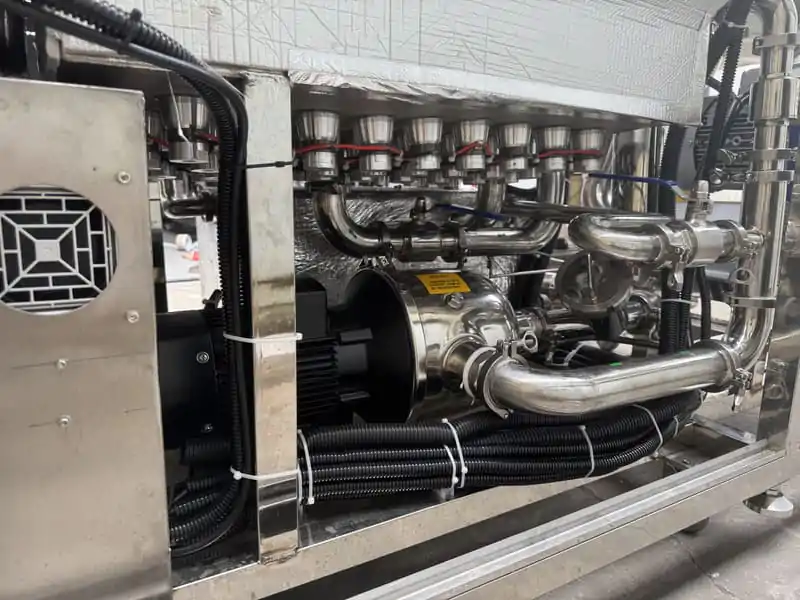

Advanced Equipment Gallery

Cutting-edge machinery and testing equipment ensuring precision manufacturing and quality assurance

Customization Capabilities

Multi-tank Options

Single, double, and multi-tank configurations tailored to your specific cleaning requirements

Frequency Range (20-200KHz)

Wide frequency spectrum from low-frequency heavy cleaning to high-frequency precision applications

Automation Levels

From manual operation to fully automated systems with robotic integration and smart controls

Quality Control System

IQC-IPQC-FQC-OQC Process

Comprehensive quality control from incoming materials to final product delivery ensuring excellence

Testing Reports

Detailed performance testing and validation reports for every equipment before shipment

Quality Certificates

ISO 9001, CE, UL, and other international certifications ensuring global compliance

Product Categories

Explore our comprehensive range of industrial ultrasonic cleaning solutions, from standard models to fully customized systems designed for your specific requirements.

Standard Models

Technical Specifications

- Tank Capacity: 3L - 200L

- Frequency Options: 28kHz, 40kHz, 80kHz

- Power Range: 100W - 3000W

- Temperature Control: RT - 80°C

Application Scenarios

Custom Solutions

Design Process Timeline

- Day 1-3Requirements Analysis

- Day 4-10Engineering Design

- Day 11-30Manufacturing & Testing

- Day 31-35Delivery & Installation

Success Stories

Not sure which solution fits your needs?

Our engineers can analyze your cleaning requirements and recommend the optimal system.

Industrial Ultrasonic Cleaning Solutions

Professional ultrasonic cleaning equipment designed for precision industries worldwide. From automotive to aerospace, we deliver micron-level cleaning solutions that meet the highest industry standards.

Automotive & Transportation

Precision cleaning for engine components, fuel injectors, brake systems, and transmission parts. Remove carbon deposits, oil residues, and metal particles with micron-level accuracy.

Electronics & Semiconductor

Ultra-gentle cleaning for PCBs, semiconductor wafers, and delicate electronic components. High-frequency systems ensure contamination-free surfaces without damage.

Medical & Pharmaceutical

Sterile cleaning solutions for surgical instruments, implants, and pharmaceutical equipment. FDA-compliant systems ensure the highest hygiene standards.

Aerospace & Defense

Critical component cleaning for turbine blades, aircraft parts, and defense equipment. Meet stringent aerospace quality standards with zero contamination tolerance.

Metal Processing & Manufacturing

Heavy-duty cleaning for bearings, molds, cutting tools, and machined parts. Remove cutting fluids, metal chips, and stubborn industrial contaminants effectively.

Optics & Precision Instruments

Delicate cleaning for optical lenses, camera components, and precision instruments. Maintain optical clarity while removing fingerprints and micro-particles.

We Also Serve

Need a Custom Solution?

Our engineering team specializes in designing bespoke ultrasonic cleaning systems tailored to your specific industry requirements and contamination challenges.

Technical Strength Display

Our advanced ultrasonic cleaning technology combines precision engineering with innovative solutions to deliver superior cleaning performance across all industrial applications.

Advanced Cavitation Technology

Multi-frequency operation (20kHz-130kHz) for versatile cleaning applications

Precision-controlled cavitation intensity for delicate component cleaning

Micron-level contaminant removal without surface damage

Intelligent Control Systems

IoT-enabled remote monitoring and real-time process control

AI-powered cleaning optimization and predictive maintenance

Automated parameter adjustment for different material types

Technical Specifications

ISO Certified Manufacturing

Our production facility meets ISO 9001:2015 quality standards with rigorous testing protocols ensuring consistent performance and reliability.

Custom Engineering

Tailored solutions designed to meet specific industry requirements with modular components for easy integration and future upgrades.

Quality Assurance

Comprehensive testing including performance validation, durability testing, and compliance verification before delivery.

Innovation at the Core

Our R&D team continuously develops cutting-edge ultrasonic technologies, ensuring our equipment stays ahead of industry demands and environmental regulations.

Service Commitment

We stand behind every ultrasonic cleaning system with comprehensive service support, ensuring your operations run smoothly from installation to long-term maintenance.

Pre-Sales Support

Free Technical Consultation

Expert analysis of your cleaning requirements and customized solution recommendations

Sample Testing Service

Send us your parts for free cleaning tests to verify effectiveness before purchase

Custom Design & Engineering

Tailored equipment design to meet your specific industry and application needs

Installation & Training

Professional Installation

Certified technicians ensure proper setup and optimal performance from day one

Comprehensive Training

On-site operator training and detailed operation manuals in multiple languages

System Commissioning

Complete testing and validation to ensure all specifications are met

Comprehensive Warranty

Technical Support

Response Time

Maintenance & Support

Preventive Maintenance

Scheduled maintenance programs to maximize equipment lifespan and performance

Remote Diagnostics

IoT-enabled monitoring and troubleshooting to minimize downtime

Genuine Spare Parts

Original components with global inventory and fast shipping worldwide

Upgrade & Optimization

Technology Upgrades

Retrofit existing systems with latest automation and IoT capabilities

Process Optimization

Continuous improvement consulting to enhance cleaning efficiency and reduce costs

Lifecycle Support

Long-term partnership with equipment modernization and expansion services

Need Service Support?

Our global service network is ready to assist you. Contact our technical support team for immediate assistance or schedule a service appointment.

Client Success Stories

Discover how our industrial ultrasonic cleaning equipment has transformed operations across various industries, delivering exceptional results and ROI for our global clients.

BMW Manufacturing Plant

Automotive Industry • Germany

Implemented our multi-frequency ultrasonic cleaning system for engine component cleaning, achieving 99.8% contamination removal efficiency while reducing cleaning time by 65%.

"The ultrasonic cleaning system has revolutionized our production line. Quality consistency improved dramatically while operational costs decreased significantly."- Klaus Weber, Production Manager

Samsung Electronics

Semiconductor Industry • South Korea

Deployed precision high-frequency cleaning equipment for semiconductor wafer processing, achieving sub-micron particle removal with zero defect rate improvement.

"Exceptional precision cleaning capability. The equipment meets our stringent cleanroom standards and has significantly improved our production yield."- Dr. Kim Min-jun, Process Engineer

Medtronic Inc.

Medical Device Industry • USA

Integrated sterile ultrasonic cleaning systems for surgical instrument processing, ensuring FDA compliance while reducing sterilization cycle time by 50%.

"Outstanding reliability and precision. The system has streamlined our sterilization process while maintaining the highest safety standards."- Sarah Johnson, Quality Assurance Director

Airbus Industries

Aerospace Industry • France

Customized large-scale cleaning system for turbine blade maintenance, achieving aerospace-grade cleanliness standards with 80% reduction in manual labor.

"Exceptional engineering and support. The custom solution perfectly meets our aerospace quality requirements while improving operational efficiency."- Pierre Dubois, Manufacturing Director

Global Impact Across Industries

Proven results from over 500+ successful installations worldwide

Ready to Join Our Success Stories?

Let us help you achieve similar results with our customized ultrasonic cleaning solutions. Contact our experts for a free consultation and system assessment.

Trust Builders

Building trust through certifications, partnerships, and proven excellence in industrial ultrasonic cleaning solutions

Certifications & Standards

ISO 9001:2015

Quality Management

CE Marking

European Conformity

UL Listed

Safety Standards

RoHS Compliant

Environmental

FCC Certified

Electromagnetic

REACH Compliant

Chemical Safety

Awards & Recognition

Innovation Excellence Award 2023

Recognized for breakthrough multi-frequency ultrasonic technology

Best Supplier Award 2022

Outstanding performance in automotive industry partnerships

Green Manufacturing Certificate

Commitment to sustainable and eco-friendly production

Trusted by Industry Leaders

Strategic partnerships with leading companies across multiple industries

Quality Guarantee

Every product undergoes rigorous testing and quality control processes

24/7 Support

Round-the-clock technical support and customer service worldwide

Extended Warranty

Comprehensive warranty coverage with optional extended protection plans

How Ultrasonic Cleaning Works

Discover the science behind ultrasonic cleaning technology and understand how cavitation creates microscopic cleaning power that removes contaminants at the molecular level.

Cavitation Process Visualization

Microscopic Bubble Formation

High-frequency sound waves create millions of microscopic bubbles in the cleaning solution, forming and collapsing thousands of times per second.

Wave Generation

Ultrasonic transducers convert electrical energy into high-frequency sound waves (20kHz-1MHz) that penetrate the cleaning solution.

Bubble Formation

Sound waves create alternating high and low pressure zones, forming millions of microscopic cavitation bubbles in the liquid.

Implosion Impact

Bubbles collapse violently, creating localized temperatures up to 5,000°C and pressures of hundreds of atmospheres, dislodging contaminants.

Basic Principles Guide

Frequency Selection

Low frequencies (20-40kHz) create larger, more aggressive bubbles for heavy-duty cleaning. High frequencies (40-200kHz) produce smaller, gentler bubbles for delicate precision parts.

Power Density

Optimal power density (typically 50-100W/L) ensures effective cavitation without damaging sensitive components. Higher power increases cleaning speed but may cause surface erosion.

Solution Chemistry

Water-based solutions with specialized detergents enhance cavitation effectiveness. Temperature control (40-80°C) and pH optimization improve contaminant dissolution rates.

Degassing Process

Fresh cleaning solutions contain dissolved gases that inhibit cavitation. A 10-15 minute degassing cycle removes these gases, maximizing cleaning efficiency.

Acoustic Streaming

Sound waves create fluid circulation patterns that enhance mass transfer, bringing fresh cleaning solution to contaminated surfaces and removing dissolved contaminants.

Micro-jet Formation

Asymmetric bubble collapse near surfaces creates high-velocity micro-jets that penetrate crevices and blind holes, reaching areas impossible with conventional cleaning methods.

Key Technical Parameters

Key Components Explained

Understanding the essential elements that make ultrasonic cleaning systems effective and reliable for industrial applications.

Frequency & Power Basics

Operating Frequency

Typically ranges from 20kHz to 80kHz, with lower frequencies providing more aggressive cleaning action

Power Density

Measured in watts per gallon, determines cleaning intensity and effectiveness for different applications

Frequency Selection

Higher frequencies for delicate parts, lower frequencies for heavy-duty industrial cleaning

Tank Design & Materials

Stainless Steel Construction

316L stainless steel provides superior corrosion resistance and durability in harsh cleaning environments

Transducer Placement

Strategic positioning on tank bottom and sides ensures uniform ultrasonic energy distribution

Drainage & Filtration

Integrated drainage systems and filtration options for continuous operation and solution maintenance

Control Systems Overview

Digital Controls

Precise temperature, time, and power control with digital displays and programmable settings

Safety Features

Automatic shut-off, overheat protection, and low-water level sensors ensure safe operation

Process Monitoring

Real-time monitoring of cleaning parameters with data logging and quality assurance features

Technical Specifications Comparison

Compare key specifications across different ultrasonic cleaning system configurations

| Component | Standard Model | Professional Model | Industrial Model |

|---|---|---|---|

| Frequency Range | 40kHz | 25/40/80kHz | 20-80kHz Variable |

| Power Output | 300W | 600W | 1200W+ |

| Tank Material | 304 Stainless Steel | 316L Stainless Steel | 316L + Coating Options |

| Control System | Basic Digital | Advanced Digital | PLC + HMI Interface |

| Temperature Control | Up to 80°C | Up to 95°C | Up to 120°C |

Benefits & Advantages

Discover why ultrasonic cleaning technology is revolutionizing industrial cleaning processes worldwide

Comparison with Traditional Cleaning

| Feature | Ultrasonic | Traditional |

|---|---|---|

| Cleaning Precision | Micron-level | Surface-level |

| Hard-to-reach Areas | Complete access | Limited access |

| Chemical Usage | Reduced by 70% | High consumption |

| Labor Requirements | Minimal | Intensive |

| Surface Damage | Non-abrasive | Potential scratching |

Efficiency Metrics

Reduces cleaning time from hours to minutes for complex components

Modern systems optimize power usage with precision control

Ensures reliable results across batches with minimal variation

Environmentally friendly with significant water conservation

Cost-Benefit Analysis

ROI Timeline

Average payback period of 12-18 months for most industrial applications

Operational Savings

30-50% reduction in overall cleaning costs including labor, chemicals, and utilities

Extended Equipment Life

Proper cleaning extends component lifespan by 25-40%, reducing replacement costs

Environmental Compliance

Reduced waste disposal costs and alignment with global environmental regulations

Before/After Gallery

See the remarkable difference our industrial ultrasonic cleaning solutions make with these visual comparisons of components before and after treatment.

Engine Valve Components

Carbon deposits and oil residue completely removed, restoring optimal performance and extending component lifespan by up to 40%.

Printed Circuit Boards

Flux residue and microscopic contaminants eliminated without damaging sensitive components, resulting in 99.8% pass rate in quality testing.

Surgical Instruments

Biological residue and contaminants completely removed, meeting strict sterilization standards with 100% compliance in bacterial testing.

Turbine Blade Components

Precision cleaning removed all microscopic particles and residues, restoring aerodynamic efficiency and passing rigorous safety inspections.

Precision Jewelry Components

Polishing compounds and microscopic debris completely removed from intricate designs without damaging delicate settings or gemstones.

Precision Optical Lenses

Fingerprints, dust, and manufacturing residues completely removed without scratching, achieving 99.9% light transmission efficiency.

See the Difference for Your Components

Send us your challenging cleaning application for a free demonstration. We'll process your sample and send you before/after images showing the results you can expect.

Special Materials Guide

Discover the optimal ultrasonic cleaning solutions for challenging materials that require specialized approaches.

Electronics & PCBs

Sensitive electronic components require gentle cleaning with higher frequencies (80-130kHz) to prevent damage while effectively removing flux residues and contaminants.

Medical Implants

Titanium and surgical-grade materials require validated cleaning processes with specialized detergents to ensure complete biocompatibility and sterilization readiness.

Aerospace Alloys

Specialized aluminum and titanium alloys used in aerospace require precise cleaning parameters to remove machining oils without causing micro-erosion or surface changes.

Optical Components

Lenses, mirrors, and optical filters require streak-free cleaning with specialized solutions that won't leave residues or affect coatings, typically using higher frequencies.

EV Battery Components

Electric vehicle battery parts require contaminant-free surfaces for optimal electrical contact and performance, using specialized cleaning processes that remove microscopic particles.

Precious Metals & Jewelry

Gold, silver, and gemstone items require gentle yet effective cleaning that preserves delicate settings and removes tarnish without damaging surfaces or loosening stones.

Need Custom Material Guidance?

Our engineering team can develop specialized cleaning protocols for your unique materials and contamination challenges.

Cost-Benefit Comparison

Compare different ultrasonic cleaning equipment options to find the best solution for your specific requirements and budget.

Long-term Benefits Analysis

| Benefit Category | Description | Estimated Value |

|---|---|---|

| Quality Improvement | Reduction in defects and rework due to superior cleaning | +12-15% yield improvement |

| Labor Efficiency | Reduced manual cleaning time and labor costs | 60-80% labor reduction |

| Environmental Impact | Reduced chemical usage and waste disposal costs | 40-50% reduction in chemical waste |

| Equipment Lifespan | Extended life of cleaned components and machinery | +30% longer component life |

Ready to make an informed decision?

Our experts can help you analyze your specific needs and recommend the most cost-effective solution.

Future-Ready Technology

Discover how our cutting-edge ultrasonic cleaning solutions are shaping the future of industrial cleaning with smart integration and sustainable innovations.

IoT & Smart Monitoring

Our next-generation equipment features IoT connectivity for real-time monitoring, predictive maintenance, and remote operation capabilities. Track cleaning parameters, receive alerts, and optimize performance from anywhere.

Eco-Friendly Innovations

Our sustainable cleaning systems reduce energy consumption by up to 30% while minimizing water usage through advanced recycling systems. Designed to meet global environmental standards and support your carbon neutrality goals.

Multi-Frequency Technology

Our adaptive frequency systems (20-130kHz) automatically adjust to optimal cleaning parameters for different materials and contaminants. Perfect for industries requiring versatile cleaning solutions for diverse components.

Research & Development

Our dedicated R&D team continuously explores breakthrough technologies in ultrasonic cleaning. We invest 15% of our annual revenue in developing next-generation solutions that address emerging industry challenges.

- Nanobubble technology for enhanced cleaning efficiency

- AI-powered contamination detection systems

- Bio-based cleaning solutions for zero environmental impact

Quantum Resonance Cleaning

Our patented technology increases cleaning efficiency by 40% while reducing energy consumption.

Structural Components

Our industrial ultrasonic cleaning equipment features precision-engineered structural components designed for durability, efficiency, and optimal performance across diverse industrial applications.

Cleaning Tank Assembly

Premium 316L stainless steel construction ensures maximum corrosion resistance and longevity. Our tanks feature welded seams with leak-proof design, optimized dimensions for uniform ultrasonic distribution, and integrated drainage systems for efficient operation.

Housing Frame

Robust steel frame construction with powder-coated finish provides structural integrity and vibration dampening for stable operation in industrial environments.

Filtration System

Advanced multi-stage filtration removes contaminants and extends cleaning solution life. Includes particle filters, oil separators, and optional activated carbon units.

Heating Elements

Precision temperature control with immersion heaters and digital thermostats. Uniform heat distribution ensures optimal cleaning solution temperature for enhanced performance.

Material & Construction Standards

All structural components meet international quality standards including ISO 9001, CE marking, and industry-specific certifications for medical, aerospace, and food processing applications.

| Component | Material | Standard |

|---|---|---|

| Tank Body | 316L Stainless Steel | ASTM A240 |

| Frame Structure | Carbon Steel | ISO 630 |

| Sealing Gaskets | EPDM/Viton | FDA Approved |

| Insulation | Mineral Wool | Fire Resistant |

Control Unit

Advanced digital control systems that provide precise monitoring, automation capabilities, and intelligent operation management for optimal cleaning performance across all industrial applications.

Intelligent Control Panel

State-of-the-art touchscreen interface with intuitive navigation, real-time parameter monitoring, and programmable cleaning cycles. Features multi-language support and user-friendly operation for enhanced productivity.

Parameter Control

Precise adjustment of frequency, power, temperature, and time settings with real-time feedback and automatic optimization algorithms.

Real-time Monitoring

Continuous monitoring of cleaning process with data logging, trend analysis, and predictive maintenance alerts for optimal performance.

IoT Connectivity

Remote monitoring and control capabilities with cloud integration, mobile app support, and Industry 4.0 compatibility for smart manufacturing.

Advanced Automation Features

Our control units integrate seamlessly with automated production lines, offering programmable recipes, batch processing, and quality assurance protocols.

Technical Specifications

| Feature | Standard Model | Advanced Model | Premium Model |

|---|---|---|---|

| Display Type | 7" LCD Touch | 10.1" HD Touch | 12" 4K Touch |

| Memory Storage | 50 Programs | 200 Programs | Unlimited Cloud |

| Connectivity | Ethernet | WiFi + Ethernet | 5G + WiFi + Ethernet |

| Data Logging | 30 Days | 1 Year | Unlimited Cloud |

| User Management | 3 Levels | 5 Levels | Custom Roles |

Electrical Modules

Advanced electrical systems designed for reliable power delivery, precise control, and optimal performance in industrial ultrasonic cleaning applications

Power Supply & Distribution

Our electrical modules feature high-efficiency switching power supplies with advanced power factor correction, ensuring stable operation across varying load conditions while minimizing energy consumption.

Generator Module

High-frequency signal generation with digital frequency synthesis technology, providing precise frequency control from 20kHz to 200kHz with automatic frequency tracking.

Protection Circuit

Comprehensive protection including overcurrent, overvoltage, overtemperature, and short-circuit protection with intelligent fault diagnosis and automatic recovery functions.

Monitoring System

Real-time monitoring of electrical parameters including power consumption, frequency stability, and load impedance with data logging and remote connectivity options.

Advanced Control Electronics

Microprocessor Control Unit

32-bit ARM processor with real-time operating system for precise timing control and advanced algorithm implementation

Power Electronics

IGBT-based power amplifiers with advanced heat management and efficiency optimization up to 95%

Communication Interface

Multiple communication protocols including Ethernet, RS485, and wireless connectivity for Industry 4.0 integration

Technical Specifications

| Parameter | Standard Range | High-Performance | Custom Options |

|---|---|---|---|

| Input Voltage | 220V ±10% | 380V ±15% | Custom Range |

| Power Output | 500W - 2kW | 2kW - 10kW | Up to 50kW |

| Frequency Range | 20-80 kHz | 20-200 kHz | Multi-frequency |

| Efficiency | ≥90% | ≥95% | ≥98% |

| Control Interface | Touch Panel | HMI + Remote | IoT Enabled |

Vibration Unit

The heart of ultrasonic cleaning technology, our vibration units deliver precise frequency control and powerful cavitation effects for superior cleaning performance across all industrial applications.

Advanced Transducer Technology

Our piezoelectric ceramic transducers convert electrical energy into mechanical vibrations with exceptional efficiency. Each unit is precision-engineered to deliver consistent performance across frequencies ranging from 20kHz to 200kHz, ensuring optimal cleaning results for your specific application.

Up to 95% energy conversion rate

50,000+ hours operation

Frequency Range Options

Low Frequency

20-40 kHz

Powerful cavitation bubbles for heavy-duty cleaning applications. Ideal for removing stubborn contaminants and thick coatings.

Medium Frequency

40-80 kHz

Balanced cleaning power and precision. Perfect for general industrial applications requiring thorough yet gentle cleaning.

High Frequency

80-200 kHz

Ultra-gentle cleaning with microscopic cavitation bubbles. Essential for delicate components and contamination-sensitive industries.

Technical Specifications

Multi-Frequency Technology

Our advanced multi-frequency systems allow real-time frequency switching during operation, optimizing cleaning performance for different contamination types and material sensitivities within a single cycle.

Adaptive Frequency Control

Automatically adjusts frequency based on load impedance and cleaning requirements

Sweep Mode Operation

Continuous frequency sweeping prevents standing wave formation and ensures uniform cleaning

Pulse Mode Capability

Intermittent operation reduces heat generation while maintaining cleaning effectiveness

Selection Guide

Finding the right industrial ultrasonic cleaner for your specific application is crucial for optimal cleaning results. Use this comprehensive guide to identify the perfect solution for your needs.

Key Factors to Consider

1. Material Compatibility

Consider the materials you need to clean. Delicate materials like thin electronics require higher frequencies, while robust parts can withstand lower frequencies with stronger cavitation.

2. Contaminant Type

Different contaminants require different approaches. Oil and grease need specific detergents, while mineral deposits might require acidic solutions and appropriate tank materials.

3. Production Volume

Your throughput requirements determine tank size, automation level, and system configuration. High-volume operations benefit from multi-tank automated systems.

4. Precision Requirements

Industries like medical devices or optics require higher cleaning standards and may need specialized features like HEPA filtration or clean room compatibility.

5. Space Constraints

Consider your facility's available space. We offer compact solutions for limited spaces or custom configurations to maximize efficiency in your workflow.

6. Budget Considerations

Balance initial investment with long-term operational costs. Energy-efficient models may cost more upfront but save significantly over time.

Frequency Selection Guide

| Frequency Range | Cleaning Power | Ideal Applications | Industries |

|---|---|---|---|

| 20-25 kHz (Low) | Aggressive cleaning with strong cavitation | Heavy industrial parts, large components with stubborn contaminants | Automotive, Heavy Manufacturing, Metal Processing |

| 28-40 kHz (Standard) | Balanced cleaning power | General purpose cleaning, most industrial applications | General Manufacturing, Automotive, Aerospace |

| 68-80 kHz (High) | Gentle cleaning with finer cavitation | Precision parts, sensitive components | Electronics, Medical Devices, Optics |

| 100-170 kHz (Very High) | Very gentle, microscopic cleaning | Extremely delicate components, micro-contamination removal | Semiconductor, Advanced Optics, Microelectronics |

| Multi-frequency | Adjustable cleaning power | Versatile applications requiring different cleaning intensities | Mixed Manufacturing, R&D Facilities, Contract Cleaning |

Industry-Specific Recommendations

Automotive & Transportation

- Recommended: Multi-tank systems with 28-40 kHz frequency

- Features: Oil separation, filtration systems, heavy-duty baskets

- Models: UT-8000 Series, AutoClean Pro Line

Electronics & Semiconductor

- Recommended: High-frequency systems (68-170 kHz)

- Features: DI water compatibility, HEPA filtration, ESD protection

- Models: PrecisionClean Series, MicroSonic Line

Medical & Pharmaceutical

- Recommended: Multi-frequency systems with validation capabilities

- Features: 316L stainless steel, GMP compliance, validation documentation

- Models: MediClean Series, PharmaUltra Systems

Aerospace & Defense

- Recommended: Customized systems with multiple frequencies

- Features: Certification compliance, process documentation, traceability

- Models: AeroClean Series, DefenseUltra Systems

System Configuration Guide

| Production Volume | Recommended Configuration | Key Features |

|---|---|---|

| Low Volume (R&D, Small Batch) | Benchtop or Single-tank systems | Compact design, manual operation, 2-20L capacity |

| Medium Volume (Small to Mid-sized Production) | Multi-tank semi-automated systems | 2-4 tanks, semi-automated transfers, 20-100L capacity |

| High Volume (Mass Production) | Fully automated cleaning lines | 4+ tanks, robotic handling, conveyor systems, 100L+ capacity |

| Custom Applications (Special Requirements) | Custom-engineered solutions | Industry-specific features, specialized materials, unique dimensions |

Need Expert Guidance?

Our team of ultrasonic cleaning specialists can help you determine the perfect solution for your specific application. With decades of experience across multiple industries, we'll ensure you get the optimal cleaning results.